Processed Raw Materials

&Treatments

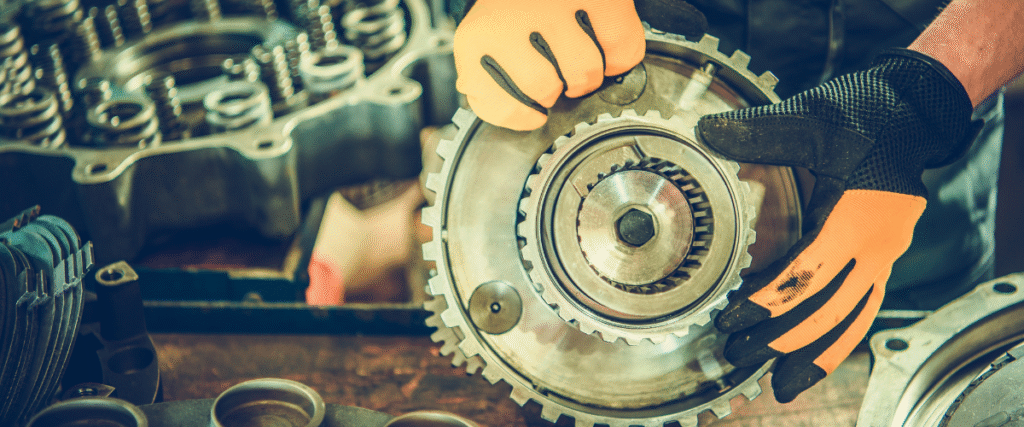

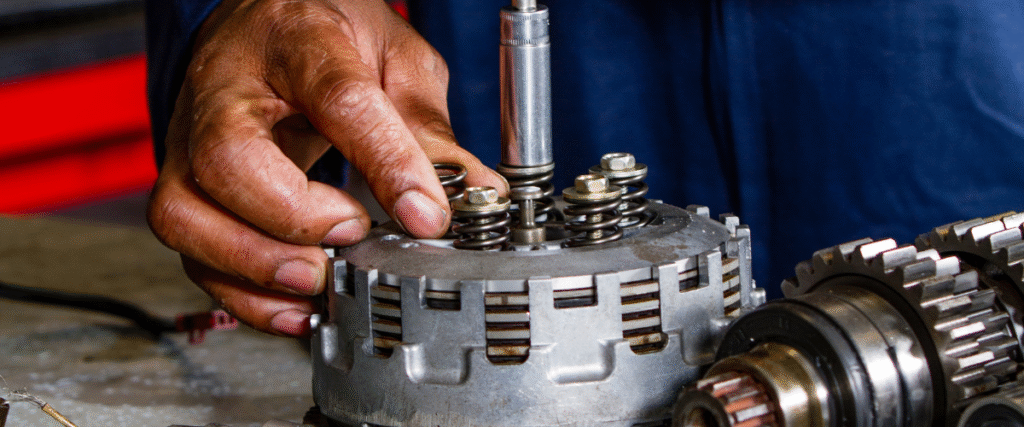

Precitech Solutions manufacturing capabilities encompass the entire gamut of precision engineering products. The synthesis of best-of-the breed machinery, technically qualified professionals and a quality-driven management policy transforms the most complex engineering drawing into a high-quality product.

The Machine shop layout has been designed to suit the line concept for mass production as well as batch production. Precitech offers an array of CNC Turning Centres, CNC Vertical Machining Centres with 4th Axis facilities along with the Gear Cutting Facility.

Sources:

- VIZAG Steel

- ARORA IRON & STEEL ROLLING MILLS PVT LTD

- ARJAS Steel

- JSW Steel

- R L Steel

- TATA Steel

Grades:

- 20MnCr5

- ST52.3

- SS304

- MS

Grades:

- EN19/42CrMo4

- EN8D

- I S2062-E350

- AL6062/6061

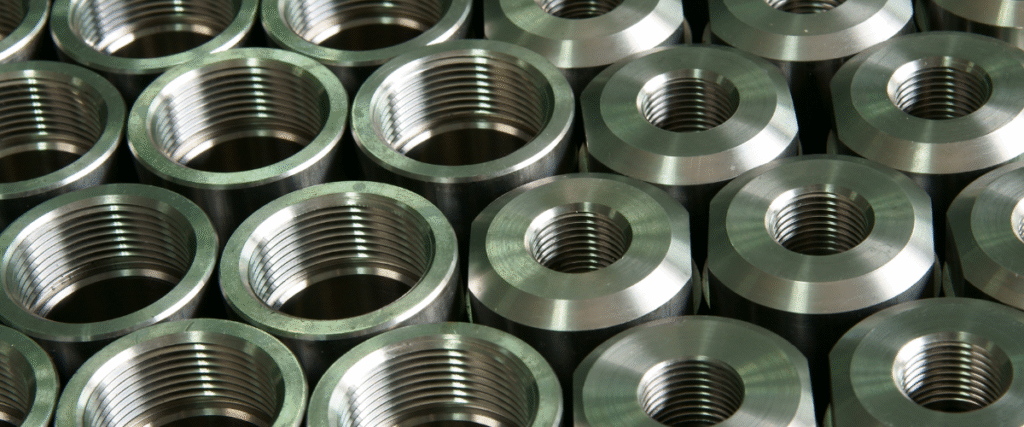

Processed Materials:

Bar Stock: Round up to Ø350mm, Hexagonal up to 110mm

Castings: Investment Casting, Shell Moulding

Forgings: Open Die (up to 180kg), Close Die (up to 60kg), Ring Rolling (up to Ø500mm)

Material Grades:

Low/Medium Carbon Steel (AISI 1018, 1020, 1040, 1045)

Alloy Steel (AISI 4140, 4340, 8620, 20MnCr5)

SS304, Aluminium 6061/6082, EC Copper, Plastics & Rubber

Precitech Solutions develop & handles diversified processed Raw material

- Any type of Casting(Investment casting, Sand casting and/or shell molding casting etc.) in material like Mild, Carbon, Stainless & Non ferrous metals like Alluminium & Copper alloys.

- rotational Resolution – Mitutoyo.

Available Treatments

Hardening Processes

- Through Hardening: A heat treatment process where the entire cross-section of a part is hardened to increase strength and hardness uniformly.

- Case Hardening: A surface-hardening technique that introduces carbon or nitrogen into the outer layer of the steel, providing a hard, wear-resistant surface with a tough core.

- Induction Hardening: Utilizes electromagnetic induction to selectively heat and harden specific areas of a part, offering improved fatigue strength and wear resistance.

Surface Treatments

- Shot and Sand Blasting: Surface cleaning and preparation method using high-speed abrasive particles to remove contaminants and create a uniform texture.

- Electroplating: A process that deposits a metal coating on a substrate using electrical current to enhance corrosion resistance and appearance.

- Zinc and Chrome Plating: Provides sacrificial protection and an attractive finish, commonly used for automotive and industrial applications.

- Phosphating: A conversion coating process that creates a corrosion-resistant phosphate layer, serving as a primer for painting or lubrication.

Special Processes

- Welding: Joining metal parts using fusion techniques for structural and mechanical applications.

- Grinding: A precision finishing process for achieving fine surface finishes and tight tolerances.

- Laser Marking: A non-contact marking method used to etch permanent identification or branding onto metal surfaces.

- Thread Rolling: A cold-forming process that creates strong, smooth, and accurate threads without cutting.

- Engraving: Mechanical or laser-based engraving used for part numbering, branding, and aesthetic detailing.

Services & Facilities

Our machining capability, Raw materials, available treatments and quality testing.

Processed Raw Materials &

Treatments

Quality Testing & Inspection

Product Development