Infrastructure

Precitech Solutions Engineered from Humble Beginnings — Powered by Quality, Innovation, and Global Vision."

Precitech began as a small manufacturing unit and has grown into a globally trusted brand — fuelled by engineering passion, uncompromising quality, and forward-thinking innovation.

- Total Land Area: 12,000 sqft

- Plant Area: 8,000 sqft

- Office Area: 1,200 sqft

- Installed Capacity: 260,000 PCPA

- Workforce: 40+

- Product Weight Range: 1 kg – 60 kg

Manufacturing areas

Skilled employee dedicated to development. Modern machines for better quality products. Scheduled quality checks to maintain quality benchmarks. And resources for FAIR & PPAP.

Very ambient work place along with canteen & recreation facility.

Dust-free assembly area to ensure manufacturing of products with quality benchmarks

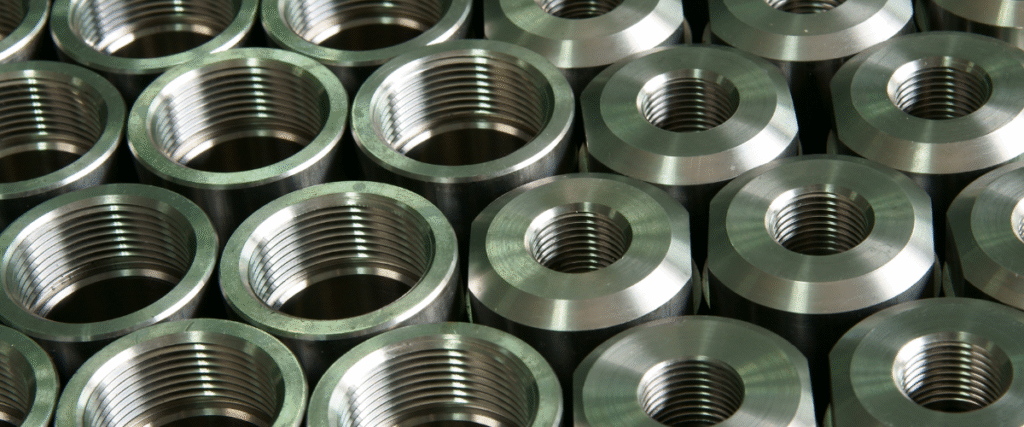

Production Machines

Our manufacturing area is Equipped with 15 CNC machines of turning center and vertical machining center, 4 CNC hobbing machines , 4 Gear shaper machines & 1 vertical broaching machines with extended capacity of 60 machines.

Production Machines

Precitech Solutions ensures manufacturing products tested with latest technology and process to meet quality benchmarks.

Production Flow Chart:

1.Steel Billets/Forgings Procurement

2.Raw Material Inspection

3.Cutting

4.Forging

5.Heat Treatment (optional)

6.CNC/VMC Machining

7.Gear Cutting (Optional)

8.Deburring

9.Final Inspection

10.Packing

11.Dispatch

Assembly Area

We have a dedicated assembly area for our sub-assembly process with a skilled and qualified team.

Growing globally, we are expanding our infrastructure with a

warehousing facility in USA and Europe.

Services & Facilities

Our machining capability, Raw materials, available treatments and quality testing.

Processed Raw Materials &

Treatments

Quality Testing & Inspection

Product Development