About Us

Precitech Solutions was engineered from humble beginnings, rooted in a small manufacturing unit with a big vision. From the very start, the company embraced a strong foundation of quality, innovation, and integrity. With a clear focus on precision and customer satisfaction, Precitech steadily built its reputation in the industry—step by step, part by part.

Today, Precitech has evolved into a globally trusted brand. Fueled by a deep passion for engineering, uncompromising quality standards, and forward-thinking innovation, the company continues to set benchmarks in the world of precision manufacturing. It proudly serves clients across the globe, shaping the future with every component it delivers.

Company Overview

- Founded in 2015 As a relatively young company, it may face challenges in competing with well-established industry leaders with decades of legacy and trust.

- High Vision Expectations The commitment to exceeding customer expectations sets a high bar, which can be difficult to consistently maintain across all operations and projects.

- Production Capacity – 260,000 Parts/Year While adequate for current operations, this capacity may become a bottleneck if rapid growth or large contracts emerge suddenly.

- 30% Spare Capacity Although spare capacity is beneficial, underutilization of this reserve could indicate inefficiencies or lower-than-expected demand in certain periods.

- Scalability Requires Investment While the company is designed to scale, actual expansion depends on timely investment in infrastructure, skilled labor, and new machinery—which can be resource-intensive.

- Dependence on Specific Industry Segments Heavy focus on automotive and agriculture sectors could pose risks if there are downturns or disruptions in these industries.

Mr. Milan Vaghashiya holds a B.E. in Mechanical Engineering from M. S. University. He brings with him a wealth of industry experience across key operational roles. He began his career in plant maintenance at SAUKEM, Porbandar, where he served for two years. He then took on the role of Head of Operations at Flexatherm Expanllow Pvt. Ltd. in Vadodara for three years, gaining hands-on leadership experience in manufacturing processes. Following that, he served as Head of Sourcing at Synnova Gears and Transmission Pvt. Ltd. for another three years, where he played a pivotal role in procurement and supply chain management.

Company Overview

CEO & Managing Director

Milan Vaghashiya

OUR VISION & PHILOSHOPY

To build an organization powered by technology and passionate individuals exceeding customer expectations.

- We strive to build an organization powered by world-class technology and driven by passionate

- individuals—committed to exceeding customer expectations every step of the way .

- To be a reliable partner for forged products in the supply chain of every engineering industry on Earth.

- We don’t just sell components—we deliver engineering excellence

- Our goal is to be a one-stop solution provider, not just to meet capabilities, but to build them

- Customer satisfaction and delight are not goals—they are our only priorities

- We don’t sell just components, but offer engineering excellence.

Why Precitech Solutions

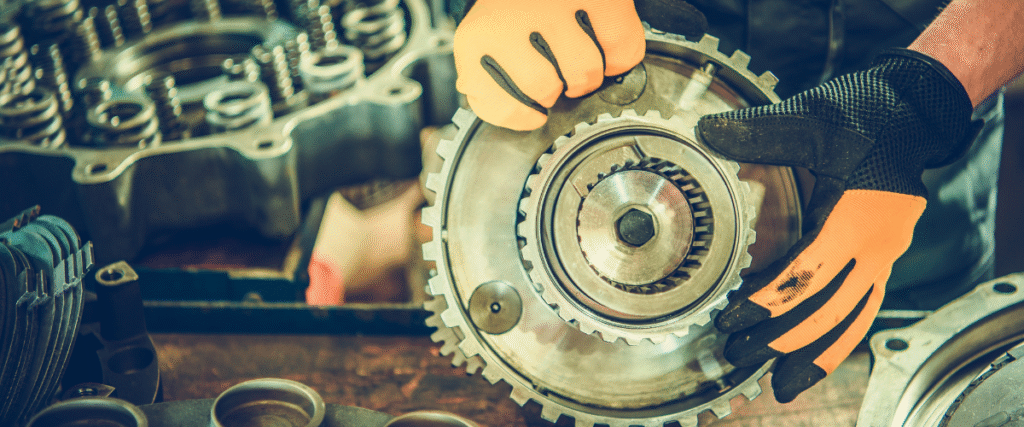

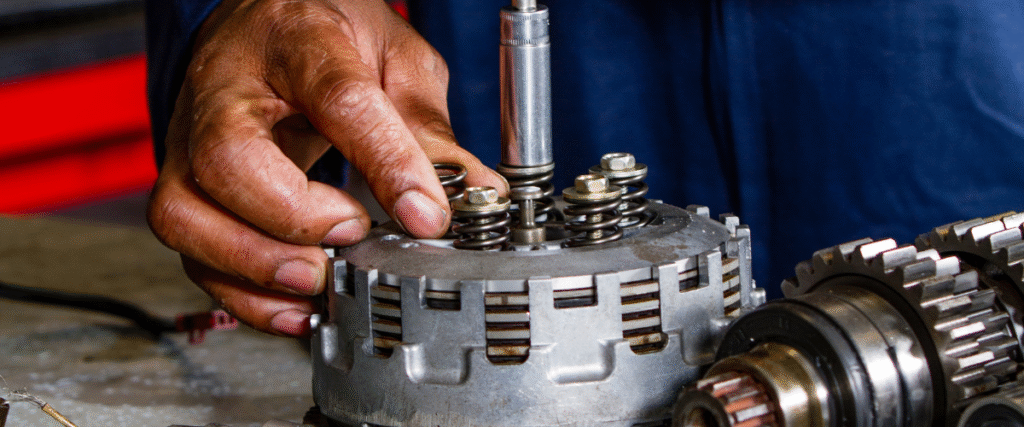

- We specialize in delivering high-strength, dimensionally accurate components using advanced hot forging and closed-die forging technologies — built to perform under extreme conditions.

- From raw material sourcing to heat treatment, machining, and final inspection, we offer integrated in-house facilities that ensure complete control over quality, timelines, and cost.

- Whether it’s mass production for OEMs or custom-built components for niche applications, our flexible manufacturing setup allows us to meet varied demands with speed and precision.

- We follow stringent quality protocols at every stage of production. Our certifications and rigorous inspection processes guarantee that each component meets global standards and customer specifications

- Our team of experts brings deep knowledge of metallurgy, design optimization, and forging simulation to deliver components that are not only strong, but smartly designed for functionality and durability.

- From automotive and agriculture to defense, construction, and railways, we serve multiple sectors with components that meet the unique demands of each application.

- At Precitech Solutions, quality is our priority—and our certifications prove it. We are proud to be ISO 9001:2015 certified, a globally recognized standard for quality management.

- Our certifications validate the systems, training, and discipline behind every forged component we deliverOur certifications validate the systems, training, and discipline behind every forged component we deliver.

- We are proudly ISO 9001:2015 certified, which confirms that our Quality Management System (QMS) meets international standards across every stage of production — from raw material procurement to final product delivery.

Human Capital

Development

Our team is updated with workshops to build skill, leadership and team bonding. They also are trained to develop their skills and apply their knowledge. We focus on building team bonding through recreational activities.

We deliver engineering excellence, not just components. Customer satisfaction is our only priority.

- At Precitech Solutions, we believe our people are our greatest asset. Through continuous training, skill enhancement, and leadership development, we foster a culture of learning and growth

- Our human capital strategy focuses on building a highly skilled, motivated, and safety-conscious workforce that drives innovation, quality, and operational excellence

- investing in our team, we ensure sustainable growth and long-term success—for our company, our employees, and our clients

- At Precitech Solutions, we recognize that forging world-class components starts with forging world-class people

- Human Capital Development is at the heart of our long-term strategy, as we believe that sustainable growth comes from empowering our workforce.

- We are committed to attracting, developing, and retaining skilled talent through structured training programs, mentorship, and a performance-driven culture

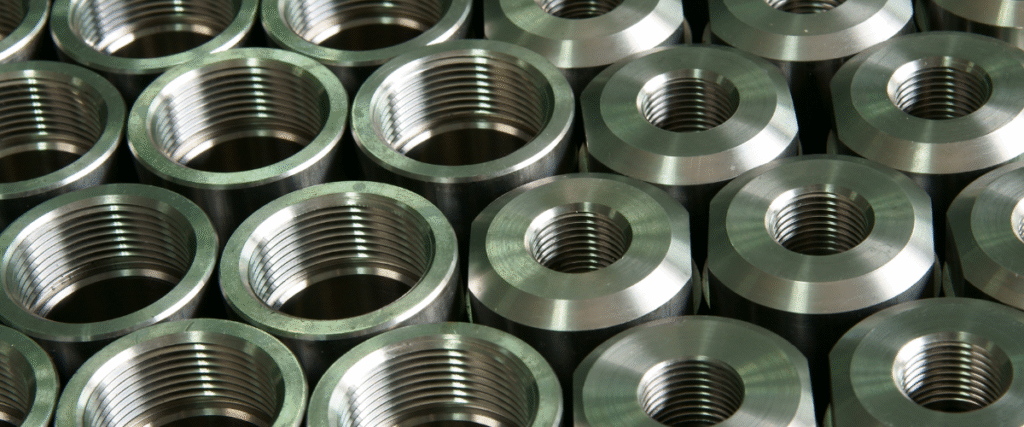

Services & Facilities

Our machining capability, Raw materials, available treatments and quality testing.

Processed Raw Materials &

Treatments

Quality Testing & Inspection

Product Development